Reducing the costs of intake equipment

Bellows type

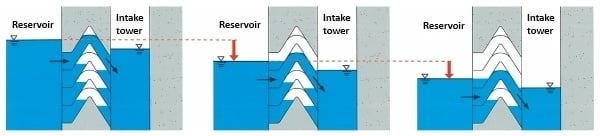

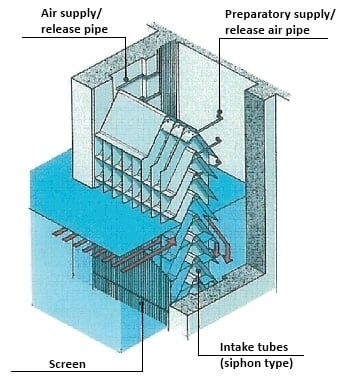

The Japan Dam Engineering Center has reduced the costs of producing dam intake equipment in various ways, and has evaluated more than 100 gates to ensure that they are safe and easy to operate. Examples of cost reduction by adopting new technologies shown in the figure are freeselective air-lock intake equipment and bellows intake equipment, which permit continuous intake as the reservoir water level varies and intake at optional depths. In the free-selective air-lock intake, a series of same shaped inverse V-shaped intake ducts are installed, and when a compressor supplies air to the intake ducts, cutting off the water (airlock), and when it exhausts air, the water passes through (forming a siphon). A characteristic of this method is that it lacks a gate and a drive unit such as an opening/closing device. The bellows type intake equipment takes in water by forming a bellows-shaped gate with a woven rubber sheet that is inexpensive, lightweight, and extremely durable installed at the location of the conventional circular multi-level gate. Because it is lightweight with a large expansion and contraction function, its opening/closing installation can be made more compact.

Operation following reservoir water level by free-selective air-lock intake equipment

Continuous siphon type intake equipment